The 3D printing industry continues to reshape modern manufacturing, moving beyond rapid prototyping into full-scale production across sectors. The global 3D printing market was valued in the tens of billions of dollars, with projections pointing to significant expansion by 2032 and 2035. This technology has real-world impact in healthcare for custom medical implants and in automotive for lightweight, complex parts. Read on for detailed trends and key statistics shaping the 3D printing landscape.

Editor’s Choice

- The global 3D printing market is projected to be worth ~$24.78 billion in 2026, expanding rapidly over the coming decade.

- Market forecasts suggest the industry could exceed $134.58 billion by 2034.

- Industry CAGR from 2025 to 2035 is estimated at ~18.5% to 20.6% across major reports.

- North America held a major share of the global 3D printing market in recent years.

- The U.S. additive manufacturing segment alone is expected to grow from $6.64 billion in 2025 to $33.83 billion by 2034.

- 3D printing services are expanding, reaching ~$8.95 billion in 2025.

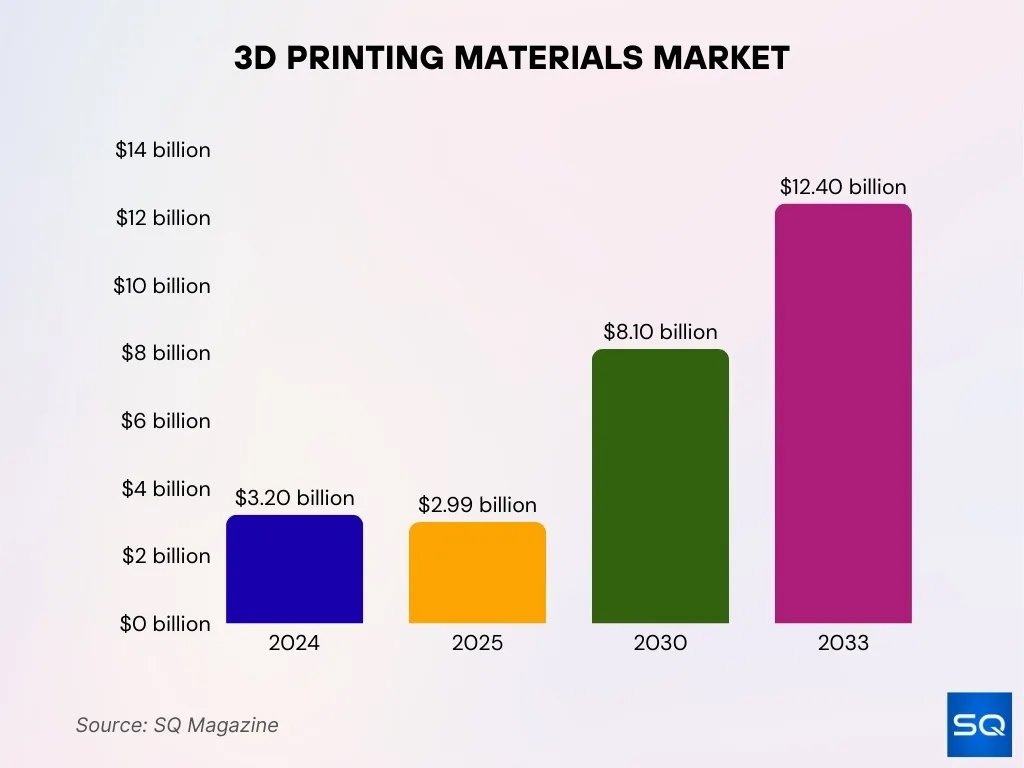

- The global materials market was about $2.99 billion in 2025, with a strong CAGR forecast to 2030.

Recent Developments

- Entry‑level 3D printer shipments surged globally in Q1 2025, with over 1 million consumer units shipped.

- Chinese manufacturers accounted for 95% of all entry‑level shipments during the same period.

- Desktop 3D printing is contributing significantly to total market value, particularly in consumer and small business segments.

- Partnerships between major players like EOS and PostProcess Technologies aim to enhance post‑processing automation.

- Adoption of metal and mixed‑material printers is increasing across industrial sectors.

- Expansion of on‑demand and distributed manufacturing services continues driving ecosystem growth.

- Sustainability efforts push 3D printing integration in recycling and waste reduction initiatives.

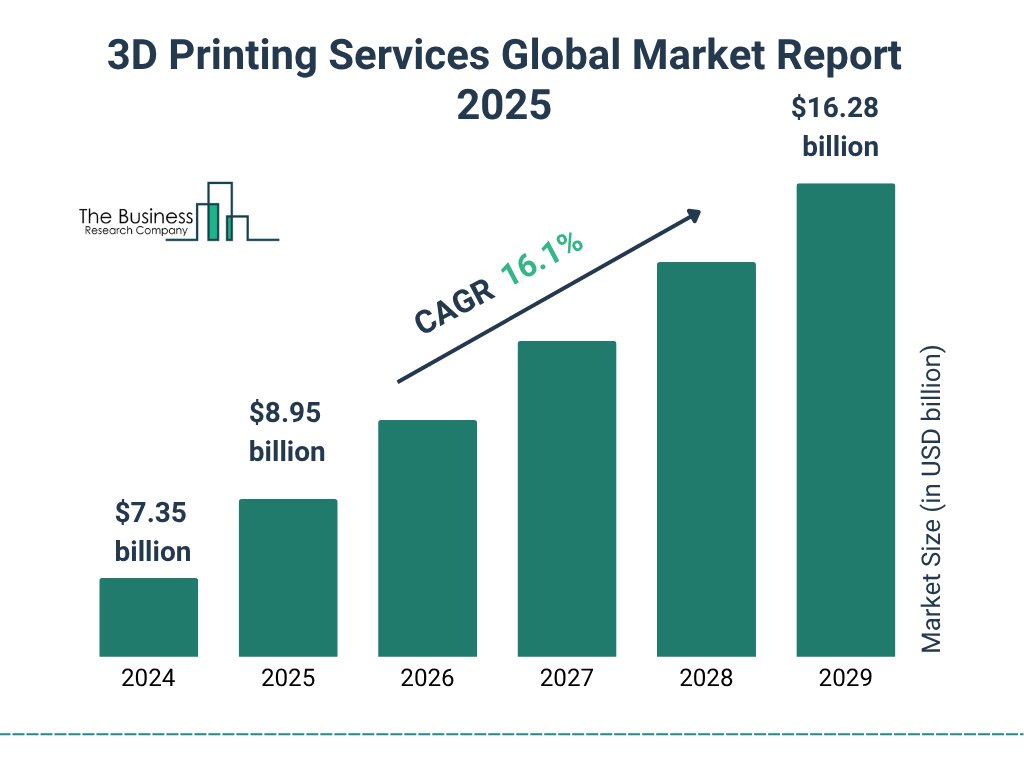

Global 3D Printing Services Market Growth

- The global 3D printing services market was valued at $7.35 billion in 2024, reflecting strong early-stage commercial adoption.

- Market size increased to $8.95 billion in 2025, showing accelerated demand across industrial and professional services.

- The market is projected to grow at a robust 16.1% CAGR during the 2024–2029 forecast period.

- By 2026, the market is expected to reach approximately $10.40 billion, driven by expanded enterprise use cases.

- Continued momentum is forecast to push the market to around $12.05 billion in 2027, highlighting sustained year-over-year growth.

- In 2028, global revenues are estimated at nearly $13.95 billion, reflecting wider adoption in manufacturing and healthcare.

- The market is forecast to hit $16.28 billion by 2029, more than doubling in size compared to 2024.

Revenue and CAGR Statistics for the 3D Printing Industry

- Across multiple sources, overall industry CAGR estimates range from ~18–24% from mid‑2020s into the 2030s.

- One forecast pegs the sector at ~20.6% CAGR from 2024 to 2035.

- Other analyses signal ~20.1% CAGR from 2025 to 2035.

- Variation in CAGR reflects differences in segment definitions and forecast horizons.

- Revenue growth aligns with wider adoption in manufacturing, healthcare, and consumer goods.

- The U.S. additive manufacturing market is expected to grow nearly fivefold from 2025 to 2034.

- Service segment revenues are also expanding at double‑digit rates.

Shipments and Install Base Trends in 3D Printing

- Entry‑level (consumer) shipments exceeded 1 million units in early 2025.

- Consumer demand is driving the expansion of desktop 3D printer installations.

- Professional and industrial shipments have fluctuated, with drops seen in early 2025.

- Industrial installation bases continue growing globally in the manufacturing and aerospace sectors.

- Adoption in education and small business contexts increases install penetration.

- Rapid prototyping remains the most common initial application for new installs.

- Mixed hardware installations (metal/plastic) are expanding in multi‑purpose facilities.

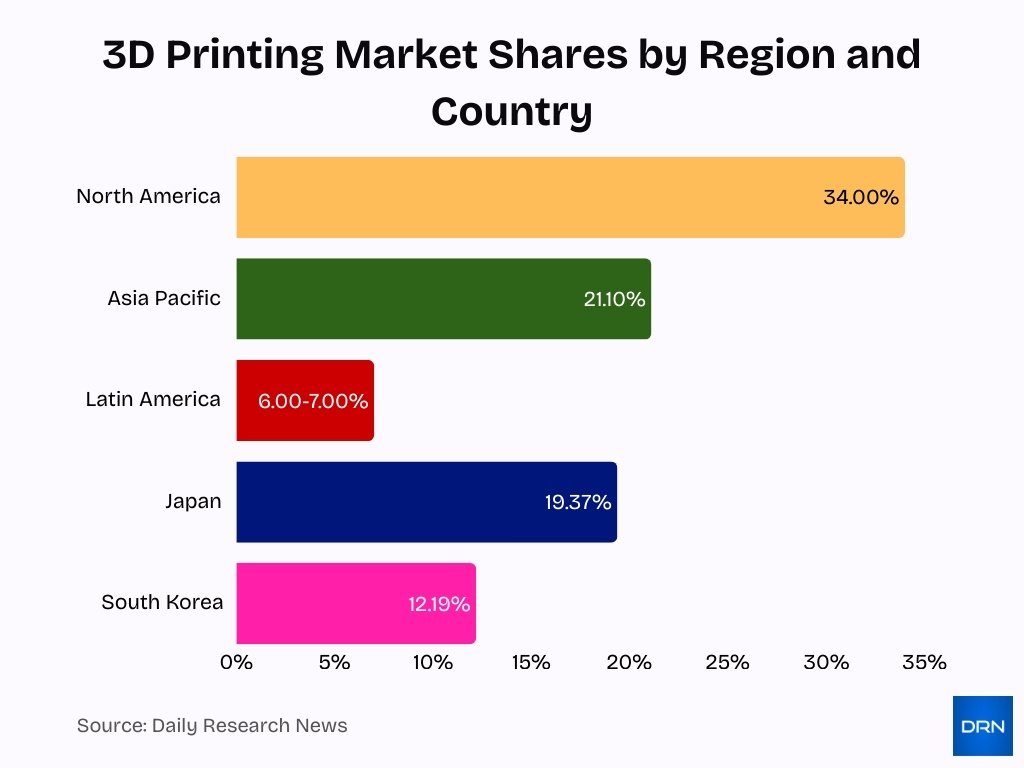

Adoption by Region and Country in 3D Printing

- North America held 34% of the global 3D printing market in 2024.

- U.S. dominated with a $5.93 billion market value in 2024.

- Europe accounted for $7.28 billion in 2024.

- Asia Pacific grabbed 21.1% market share in 2025.

- China installed 15,000 industrial 3D printers in 2025.

- Japan captured 19.37% of the Asia Pacific market in 2025.

- South Korea held 12.19% share in the Asia Pacific in 2025.

- Latin America represented 6-7% of the global market in 2024.

- Middle East & Africa healthcare 3D printing reached $431.76 million in 2024.

Automotive and Transportation Insights on 3D Printing

- Major automakers increasingly use 3D printing for rapid prototyping and tooling, reducing lead times by up to 50%.

- The use of additive manufacturing in automotive has helped companies produce lightweight structural parts, improving fuel efficiency.

- Startups like Divergent 3D apply advanced printing to build high‑performance automotive structures such as the Czinger 21C hypercar.

- Manufacturers integrate 3D printed components into electric vehicles (EVs) to optimize weight and battery range.

- Automotive suppliers now deploy 3D printing to produce custom fixtures, tools, and jigs on demand.

- The industry’s shift to multi‑material printing supports broader use in interiors and functional assemblies.

- 3D printing enables localized production, potentially reducing logistics costs and carbon emissions.

- Adoption of additive manufacturing in transportation can cut part production times from weeks to days.

Aerospace and Defense Applications of 3D Printing

- The aerospace & defense sector continues to lead in lightweight, high‑performance components via 3D printing.

- Airlines and OEMs use additive manufacturing for turbine blades, ducting, and structural parts to reduce weight and fuel usage.

- Defense agencies fund research to improve materials and multi‑material printing capabilities for rugged environments.

- Printing with advanced metals like titanium and superalloys enhances component thermal resistance and strength.

- Composite and metal additive processes shorten supply chains and increase part availability in remote theaters.

- The sector’s focus on durability drives investment in high‑precision additive systems with tight tolerances.

- Aerospace firms use 3D printed parts to reduce assembly complexity and part counts.

- Validation and certification initiatives expand opportunities for end‑use additive manufacturing in safety‑critical applications.

Healthcare and Medical Devices Using 3D Printing

- The global 3D printing medical devices market was valued at about $3.16 billion in 2024.

- This sector is projected to reach approximately $11.46 billion by 2032 at a ~17.5% CAGR.

- Hospitals use 3D printing to produce patient‑specific implants and prosthetics tailored to anatomical requirements.

- Dental applications, including crowns, bridges, and aligners, represent a growing use case globally.

- Bioprinting research is advancing toward tissue engineering and regenerative medicine solutions.

- Custom surgical guides created by additive manufacturing improve precision and reduce operating time.

- Medical device companies integrate 3D printed components to accelerate product development.

- Regulatory approvals for new materials expand broader adoption in clinical settings.

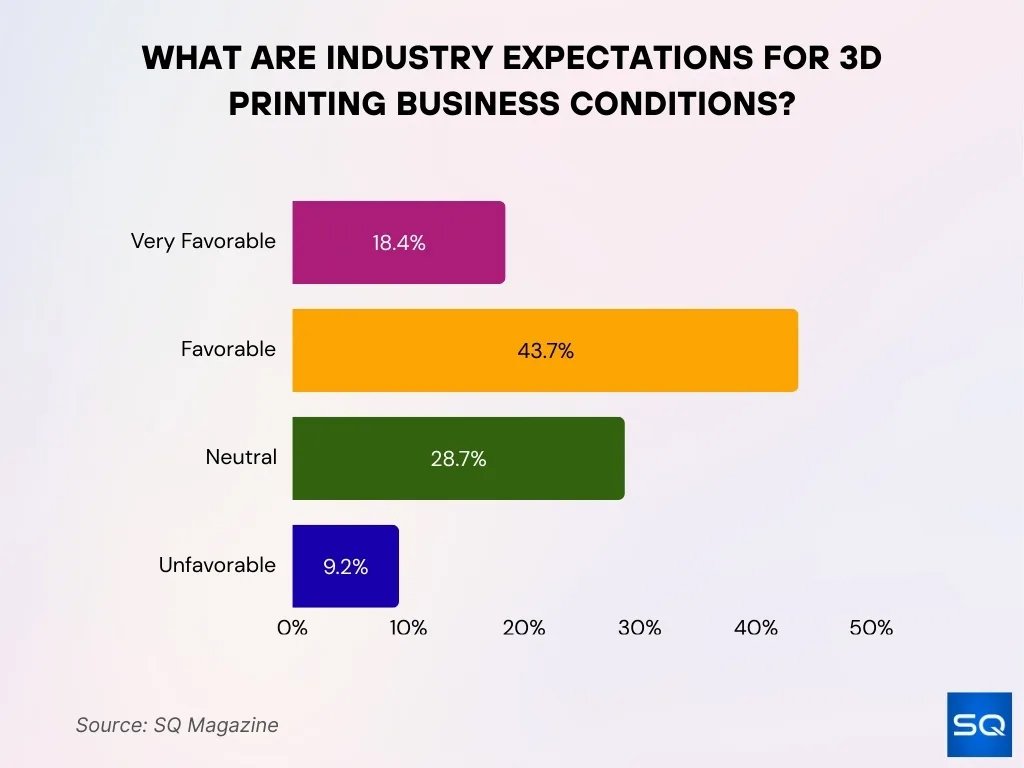

Industry Outlook on 3D Printing Business Conditions

- 43.70% of respondents anticipate favorable business conditions in 2025, signaling a broadly positive outlook across the industry.

- 28.70% feel that conditions will stay neutral, reflecting a tone of measured confidence and cautious optimism.

- 18.40% predict very favorable outcomes, highlighting strong confidence in the future growth of the sector.

- 9.20% expect an unfavorable business environment, indicating a relatively low level of concern overall.

Consumer Products and Electronics Using 3D Printing

- The 3D printed electronics market is forecast to grow from around $12.09 billion in 2025 to ~$13.95 billion in 2026.

- It’s expected to hit about $49.22 billion by 2035 at a ~15.1% CAGR.

- Consumer brands like Apple use additive manufacturing to 3D print titanium watch components, cutting material waste by half.

- Electronics manufacturers leverage 3D printed casings and housings to enable rapid design iterations.

- 3D printing supports wearable tech customization, especially in small batch runs.

- Hobbyists and makers use desktop printing for DIY gadgets and prototypes.

- 3D printed parts address fit and ergonomic customizations in consumer devices.

- Advanced printed electronics play roles in IoT devices and smart sensors.

Technology Type Trends in 3D Printing (FDM, SLA, etc.)

- FDM holds the largest market share at 35.7% in the 3D printing market in 2025.

- FDM commands 42% of the 3D printing materials market share in 2025.

- SLA 3D printing market reaches $3.04 billion in 2025, growing at 21.79% CAGR.

- SLA market projected to hit $3.5 billion by 2033 with 12.5% CAGR from 2025.

- The metal 3D printing market is valued at $7.5 billion in 2025, expanding at 22.8% CAGR.

- DMLS and EBM drive 25% CAGR growth in healthcare metal printing through 2030.

- The SLS market size stands at $5.00 billion in 2025 for automotive functional parts.

- SLS grows fastest at 18.53% CAGR in automotive 3D printing through 2030.

- The multi-jet fusion market is valued at $3.33 billion in 2025, with 19.8% CAGR.

- Binder jetting services reach $145.5 million in 2025, growing at 16.2% CAGR.

- The hybrid additive machines market hits $3.1 billion in 2025, at 23.5% CAGR.

- The material jetting process is valued at $2.7 billion in 2024, growing at 10.99% CAGR.

Desktop vs Industrial Usage of 3D Printing

- The desktop 3D printing market reached $6.7 billion in 2025, growing at 12.3% CAGR to $11.9 billion by 2030.

- Industrial 3D printers hold 71% revenue share in the overall 3D printers market in 2024.

- Desktop FDM printers are priced $150–$1,000, while industrial systems exceed $100,000.

- Nearly 1 million desktop 3D printers under $2,500 shipped globally in Q4 2023 alone.

- 3D printing in the education market is valued at $370 million in 2024, projected to reach $823.9 million by 2033.

- The aerospace 3D printing market hit $3.67 billion in 2024, forecasted to reach $19.26 billion by 2032 at 23.44% CAGR.

- Metal 3D printing for industrials is valued at $7.5 billion in 2025, reaching $38.81 billion by 2033.

- 83% of labs use 3D printing in-house or outsourced in 2025, up 20 points since 2021.

- Over 220 SMEs in one Indian zone adopted in-house 3D printing for prototyping from 2022–2024.

- Prototyping accounts for over 55% of global 3D printing revenues in 2024.

Materials Market Size and Growth in 3D Printing

- The worldwide 3D printing materials market reached a valuation of $3.2 billion in 2024 and is expected to expand to nearly $12.4 billion by 2033, registering a ~15.6% CAGR during 2025–2033.

- An alternative projection estimates the materials market at $2.99 billion in 2025, increasing to $8.10 billion by 2030, reflecting a strong ~22.05% CAGR.

- Based on material type, plastics (polymers) accounted for approximately 47.25% of the total materials market share in 2024.

- By form factor, filament led overall revenues in 2024, capturing a dominant ~68.4% revenue share.

- Ceramics and composites are seeing growing adoption, although they continue to expand from relatively smaller base volumes.

- Major industries fueling materials demand include aerospace & defense with intensive metal usage, automotive leveraging both metal and polymer materials, and medical and dental sectors relying on biocompatible polymers and metals.

Hardware, Software, and Services Revenue from 3D Printing

- The global 3D printing market generated about $20.37 billion in revenue in 2023 and is forecast to grow significantly by 2030.

- The hardware segment accounted for the largest revenue portion at $12.96 billion in 2023.

- Analysts project the total 3D printing market could rise to ~$35.79 billion by 2030 from $16.16 billion in 2025, hardware, software, and services combined.

- The 3D printing services market is estimated to grow from ~$7.35 billion in 2024 to $8.95 billion in 2025 at ~21.7% CAGR.

- Services revenue is expected to reach roughly $16.28 billion by 2029, reflecting demand for digital twinning and on-demand production.

- Software, although a smaller share than hardware, is increasingly critical for workflow, simulation, and design.

- Investments in integrated hardware‑software workflows are rising to support industrial automation.

- Expansion in services and software revenues aligns with growth in custom solutions across healthcare and aerospace.

Prototyping vs Production Use in 3D Printing

- The 3D printing for prototyping market is expected to grow from about $23.07 billion in 2025 to $58.01 billion by 2030 at a ~20.3% CAGR.

- An alternative estimate suggests prototyping may be worth ~$11.67 billion in 2025, expanding to $24.16 billion by 2030.

- Prototyping applications continue to dominate by volume, particularly in consumer goods and industrial design.

- Production use is increasingly viable as materials and machine precision improve for end‑use parts.

- Industrial 3D printing installations show rising use for production in aerospace, medical devices, and automotive manufacturing.

- The divide between prototyping and production workflows is narrowing as design‑for‑additive practices mature.

- Production use is rising where low‑volume runs and complex geometries justify additive costs over subtractive manufacturing.

- Increased automation and quality controls help shift more use cases toward full production readiness.

Customization and On-Demand Manufacturing via 3D Printing

- The industrial 3D printing market reached $4.31 billion in 2025, projected to hit $24.03 billion by 2034 at a 21.04% CAGR.

- 82% of businesses report substantial cost savings from 3D printing in manufacturing pipelines.

- 47% of users select 3D printing primarily to slash lead times over traditional methods.

- 76% of surveyed firms print production runs exceeding 10 parts, with 6.2% over 1,000 parts.

- 70% of manufacturers printed more parts in 2023 than in 2022, boosting on-demand production.

- 3D printing cuts jigs and fixtures lead times by 60–90% in aerospace assembly lines.

- 80% of manufacturing companies achieve reduced lead times via 3D printing for custom tooling.

- The 3D printed medical implants market was valued at $2.19 billion in 2023, growing to $6.59 billion by 2032.

- Additive manufacturing reduces material waste by up to 90% compared to subtractive methods.

- 30% of manufacturers view 3D printing as key to restructuring supply chains and minimizing inventory.

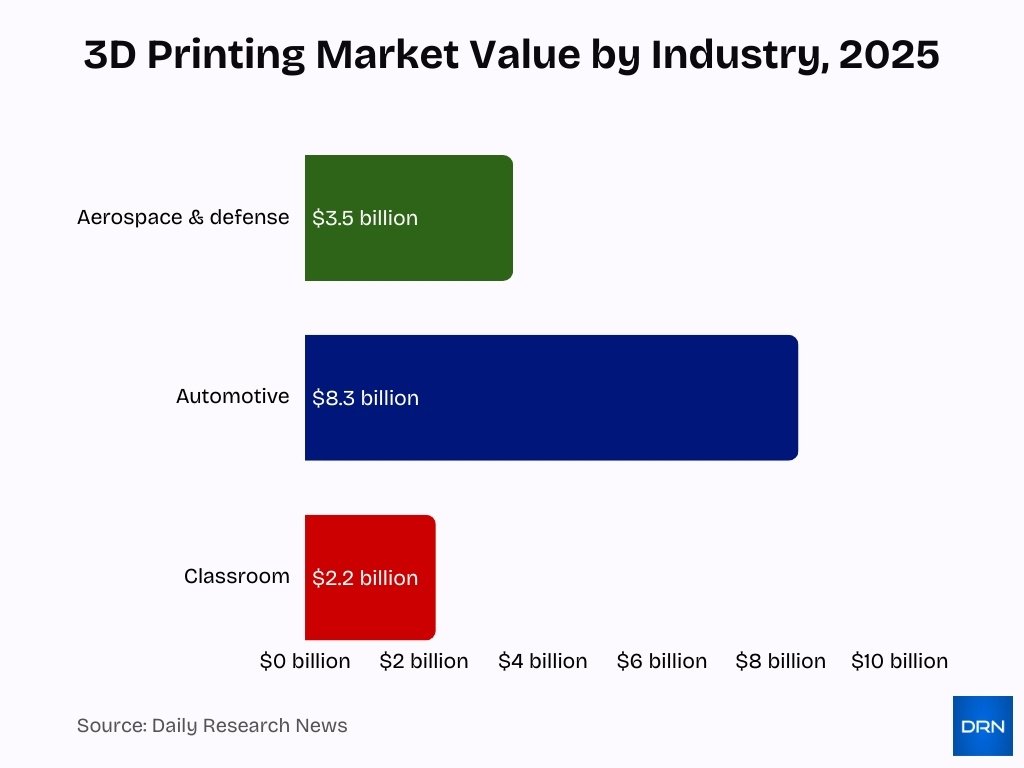

Adoption by Industry Verticals in 3D Printing

- Healthcare produced 19.4 million 3D-printed medical components in 2025.

- Patient-specific implants in healthcare exceeded 3.2 million units in 2025.

- The aerospace & defense 3D printing market reached $3.5 billion in 2025.

- Aircraft holds 60% share in aerospace 3D printing adoption.

- Alloys dominate 65% of materials in aerospace & defense 3D printing.

- The automotive 3D printing market is valued at $8.3 billion in 2025.

- Automotive captures 29.6% share of the global 3D printing verticals.

- The education 3D printing market hit $455.8 million in 2025.

- Classroom 3D printing reaches $2.2 billion in 2025.

Startups, Investments, and Funding in 3D Printing

- 3D printing continues to attract startup investment, with notable funding rounds across sectors.

- Firestorm Labs, focused on drone‑printing and mobile factories, secured $47 million in Series A funding in 2025.

- Advanced materials and software ventures also draw capital for growth in aerospace and automotive markets.

- Industry R&D expenditures grow, reflected in partnerships between OEMs and tech startups.

- Equipment vendors continue innovation in printers and materials, often backed by venture capital.

- Universities and research labs partner with startups to commercialize next‑gen additively manufactured systems.

- Investments in software tools that integrate generative design and simulation are increasing rapidly.

- Expansion of startup ecosystems reflects broader industry confidence as 3D printing moves into production‑grade applications.

Market Forecast and Future Outlook for 3D Printing

- Multiple forecasts predict the 3D printing market will grow from ~$40.6 billion in 2025 to $252.5 billion by 2035 at about 20.1% CAGR.

- Precedence Research estimates the market will exceed $134.58 billion by 2034 from ~$29.29 billion in 2025.

- Verified Market Research projects a rise to ~$162.67 billion by 2031, up from $29.81 billion in 2024 at ~23.6% CAGR.

- Grand View and other analysts suggest aggressive hardware growth, particularly in the industrial and healthcare sectors.

- Continued integration of AI, IoT, and automation will accelerate additive manufacturing adoption.

- Future outlook includes more localized, decentralized manufacturing, fueled by on-demand networking platforms.

- Material science advancements will enable broader application ranges with higher-performance materials.

- Regulatory and certification pathways expanding for critical sectors will open production-scale deployment.

Frequently Asked Questions (FAQs)

$35.79 billion (from $16.16 billion in 2025 at ~17.2% CAGR).

Approximately $17.59 billion, growing from $3.19 billion in 2025 at ~18.36% CAGR.

Around $252.5 billion, expanding from $40.6 billion in 2025 at ~20.1% CAGR.

Roughly 21.04% CAGR as the market grows toward $24.03 billion by 2034.

Conclusion

The 3D printing industry stands at a transformative point. Current trends show robust market growth, notably in materials, hardware, and services, with projections pointing toward triple‑digit billion‑dollar totals within a decade. Adoption isn’t limited to prototyping anymore; production, customization, and on-demand manufacturing use cases are growing across healthcare, automotive, aerospace, and consumer electronics.

Startups and established players alike continue to push boundaries, driven by investments and rapid advances in technology. As the ecosystem matures, 3D printing will increasingly reshape global manufacturing strategies and supply chains, bringing complex, customized products from design to reality faster than ever before.